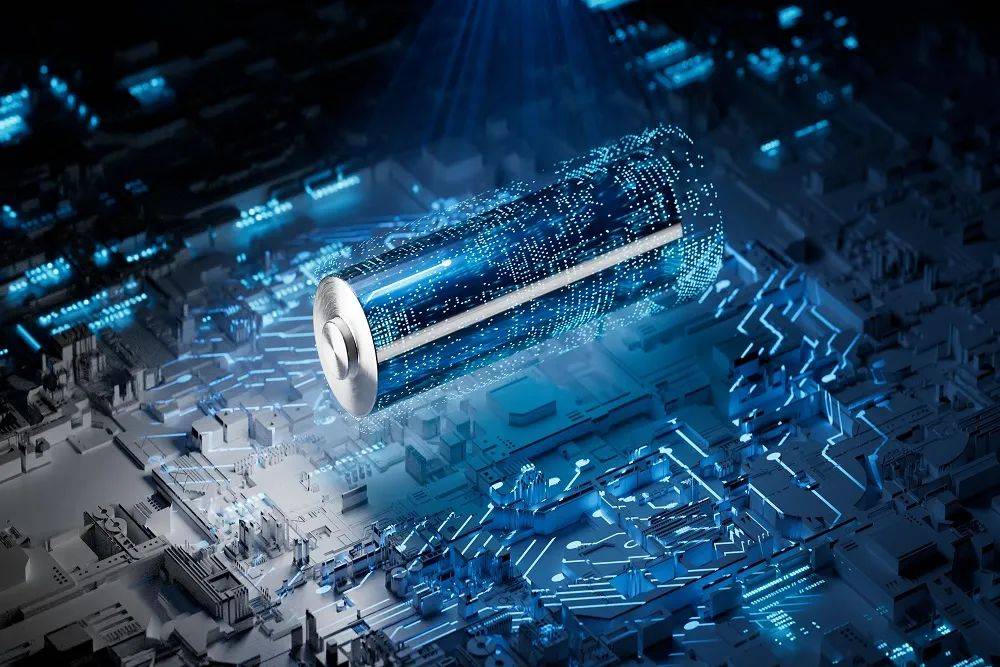

Recently, Chinese scientists have successfully overcome the technical challenge of "solid-solid interface contact" in all-solid-state metal lithium batteries, achieving a leapfrog upgrade in battery performance. Previously, a 100-kilogram battery could support a maximum range of 500 kilometers. Now, it is expected to break through the 1,000-kilometer ceiling. This breakthrough will have a profound impact on the electronic components industry.

A research team from the Institute of Physics, Chinese Academy of Sciences and other institutions has solved the core problem of poor interface contact between solid electrolytes and lithium metal electrodes. Researchers have developed an "anion regulation technology" by introducing iodide ions into sulfide electrolytes. These ions will automatically fill the tiny gaps at the interface between the electrode and the electrolyte during battery operation, keeping the two in close contact at all times. Meanwhile, the flexible electrolyte developed by the Institute of Metal Research, Chinese Academy of Sciences, can be bent more than 20,000 times, significantly enhancing the battery's durability and increasing its power storage capacity by 86%. The research team from Tsinghua University has modified the electrolyte with fluorinated polyether materials, taking advantage of fluorine's extremely strong high-voltage resistance to form a protective layer on the electrode surface, achieving a dual breakthrough in safety and battery life.

With the breakthrough of technical bottlenecks, the industrialization process of solid-state batteries has significantly accelerated. Dongfeng Motor has successfully developed a solid-state battery product with a capacity of 350Wh/kg, which has passed rigorous tests such as puncture, 50% compression large deformation, and a 150℃ high-temperature hot box. At present, Dongfeng Motor has built a 0.2GWh solid-state battery cell pilot production line. The first batch of 350Wh/kg solid-state battery cells has been rolled off the production line, and the construction of mass production lines is being accelerated. Industry experts predict that 2026 will be the first year of the solid-state battery industry. Globally, companies like Toyota have also announced plans to launch their first models equipped with mass-produced all-solid-state battery technology in 2027.

This technological breakthrough will bring new development opportunities to the electronic components industry. The significant increase in the energy density of solid-state batteries has put forward higher requirements for battery management systems, necessiting more precise power metering chips and more reliable battery monitoring and protection circuits. As battery life improves, fast charging technology will become a necessity, which will drive the growth in demand for SiC and GaN power devices, while requiring more efficient charging chips and safer circuit protection designs. Although all-solid-state batteries are inherently safe, the entire power system still requires meticulous monitoring and protection, which will create new demands for high-precision temperature sensors, current/voltage sensors and other components. In addition, the mass production of solid-state batteries requires new production line equipment, such as isostatic pressing equipment and laser equipment, which will drive the demand for industrial electronic components such as high-precision sensors, lasers, and motion controllers.

According to research institutions' predictions, by 2030, the global shipment volume of solid-state batteries will reach 614 gigawatt-hours, among which all-solid-state batteries will account for nearly 30%. This development trend will significantly boost the demand for upstream metals such as lithium, nickel, cobalt, manganese and zirconium. Experts predict that all-solid-state batteries will be the first to be applied in special fields where costs are relatively less sensitive, such as low-altitude economy, hybrid power or high-temperature drilling platforms. At present, nearly 30 domestic enterprises have announced that they will commercialize solid-state batteries by 2025 to 2030, and the technical route is becoming increasingly mature. Industry experts point out that the breakthrough in solid-state battery technology not only affects the energy storage field but also triggers a chain reaction in the electronic components industry. From BMS to power devices, from sensors to protection components, every link in the industrial chain is brewing changes, which will bring a new round of development opportunities to electronic component enterprises.

Disclaimer: The article is sourced from the Internet. In case of any dispute, please contact customer service.